QUALİTY

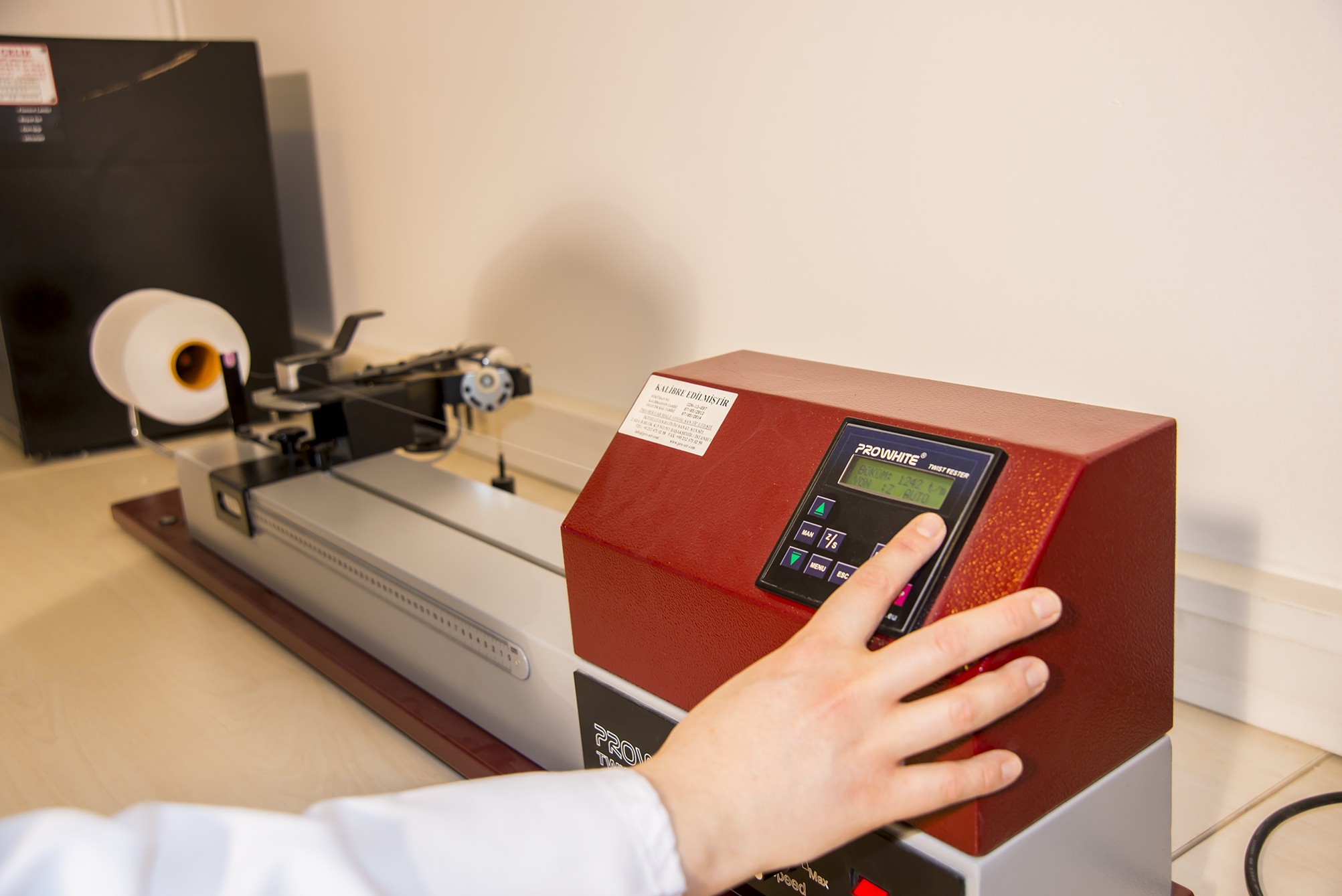

Thanks to the physics laboratory that we established in our facilities, we test the products and incoming raw materials and try to avoid problems in the production process and warn our customers. Particularly, with the controls we carry out in socks knitting and sample dye tanks, we provide better services to our customers.

All tests and reports before production.

In pre-fixation preparations section, yarns are visually checked and prepared for fixing process. Fixation process applied in our premises is controlled with a fully electronic software. Each step of the process is recorded visually and in writing which allows us to provide services to our customers by eliminating fixing differences.

After the final stage of production, i.e. fixation, coils are individually checked in the quality control process, barcoded and sorted with 50-gr range. Thus, wastage and production losses of our customers are minimized.

No matter if one package or one million packages, they are all handled with the same care.